Email:

[email protected]

Tel:

+86 17864107808

- Home

-

Products

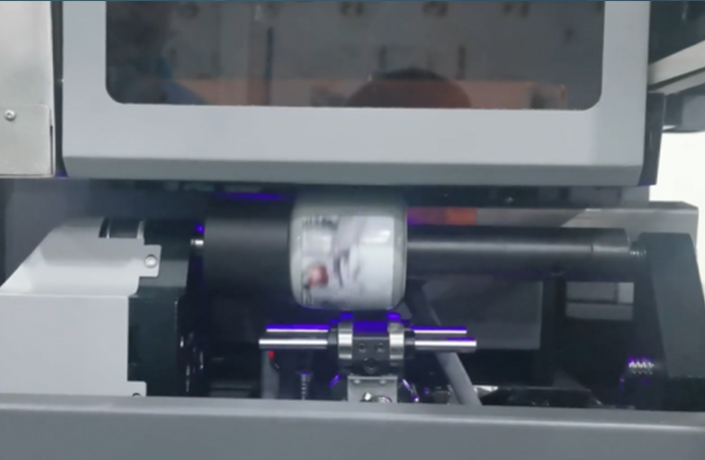

UV Flatbed PrinterSmall UV Flatbed PrinterMedium UV Flatbed PrinterLarge UV Flatbed PrinterHigh Speed Printing PressSN-ONEPASS PrinterHigh Speed Label Printing MachineHigh Speed Fishing Rod Printer

- Products

- Project

- Hot product

- Online learning

- After-sales service

- About us

- Blog

- Contact us

一级标题

一级标题